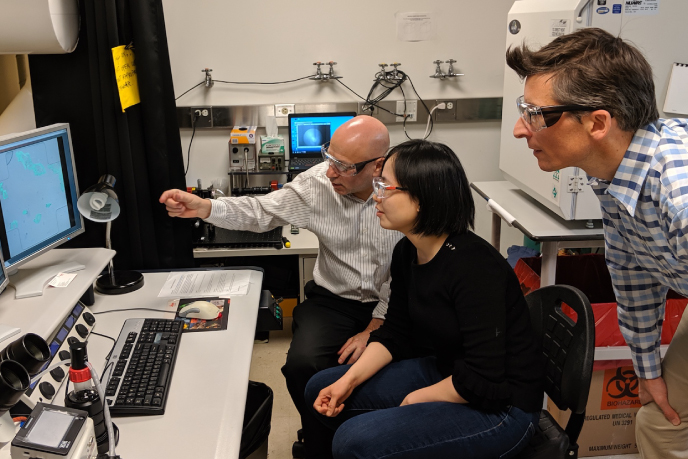

A visit of Prof. Stefano Consonni and three research associates from Politecnico di Milano in the spring of 2007 helped deepen and expand the analysis of novel technological options for CO2 capture. Joint work through a triangular connection among bp, Princeton, and the Politecnico has focused on a number of particularly promising technological and system options for CO2 capture. With this framework in mind, a formal agreement between bp and the Politecnico has been discussed which would take advantage of the capabilities being developed at the new LEAP lab in Piacenza, and could also include also experimental investigations on the thermodynamic properties of supercritical CO2 mixtures, an area where significant work is needed to substantiate the performance estimates of capture technologies.

One further opportunity to develop collaborative work between Princeton and Milano comes from the contacts established by both Universities with Prof. Li Zheng at Tsinghua. In November, Li and Dr. Christos Papadopoulos joined a group from Politecnico and Princeton in their visits to two of the four large IGCC plants fed with petroleum tar operating in Italy. Talks are underway to define a joint project, possibly funded by the bp Clean Energy Center at Tsinghua, to simulate the off-design behavior of gasification plants – a topic relevant to most systems with precombustion capture.

The research currently being pursued in collaboration with Politecnico falls in the five areas described below:

Cryogenic capture

Following preliminary, positive indications emerged from a screening carried out by the Carbon Capture Group in bp Alternative Energy, work has been carried out to simulate and assess the performance (in terms of power consumption and fraction of CO2 captured) of cryogenic pre-combustion capture in IGCCs (Figure 3). The novelty of the configurations considered and the preliminary results obtained so far have led bp Alternative Energy to suggest an assessment of the prospects for patent protection. Further investigations will resume soon after clarifying this issue, with the continued involvement of Dr. Federico Viganò.

Coal-biomass co-gasification with CCS

If coupled with CCS, the co-gasification of coal and biomass allows the production of fuels with low (possibly zero) content of fossil carbon without being penalized by the small scale suited to systems fed only with biomass. On the other hand, the use of biomass in modern, pressurized entrained flow coal gasifiers is problematic due the low heating value of biomass and its unfavorable physical features that make it difficult to feed biomass in such gasifiers. A comprehensive analysis of the available technologies and the possible plant configurations that could be adopted for co-gasification has been carried out to identify the most promising options for large scale plants where biomass and coal are co-gasified to produce Substitute Natural Gas (SNG). Despite concerns about its (possibly inadequate) market price, the production of SNG with non-fossil carbon opens the possibility to distribute it through the existing large infrastructure for natural gas at very low cost. Preliminary heat/mass balances and performance estimates have been generated for a large scale plant where the unconverted syngas left downstream of the SNG reactors feeds a state-of-the-art combined cycle.

Assessment of Shell quench gasification and optimization of integrated steam cycles

With a recent patent Shell has introduced a variation of its entrained flow gasification technology meant to be particularly suited to IGCC with CCS. In such new “quench” version, the syngas exiting the gasifier is quenched with a spray of water rather than being cooled in a heat exchanger to generate high pressure steam. The negative impact on efficiency is somewhat compensated by the higher water content of the syngas, which facilitates the water-gas shift to be carried out downstream. The new technology has been modeled in detail and compared with the “conventional” Shell technology with syngas cooler. Results will be reported in a paper under preparation that will discuss the potential of the new technology for applications with CCS.

Optimization of integrated steam cycles

In a gasification system with co-production of fuels and electricity, the steam cycle is fed by a large number of inputs (heat recovery from various sources at different temperatures) and may supply a large number of auxiliary processes. As part of the Thesis of Emanuele Martelli, a Ph.D. student at Politecnico among the ones who have visited PEI, a new method is being developed to optimize the configuration and the operating parameters of the steam cycle. The novel and most relevant feature of the method is its capability to identify the optimal configuration of the heat exchanger network as part of the solution of the optimization algorithm, rather than predetermining the configuration ahead of optimizing the operating parameters.