Experimental studies and geochemical modeling to be carried out in the next two years should predict the most important variables affecting leakage rates within a well. This information will be combined with statistical information about well properties to provide input for the semianalytical and coarse resolution models developed by Mike Celia and colleagues for risk assessment.

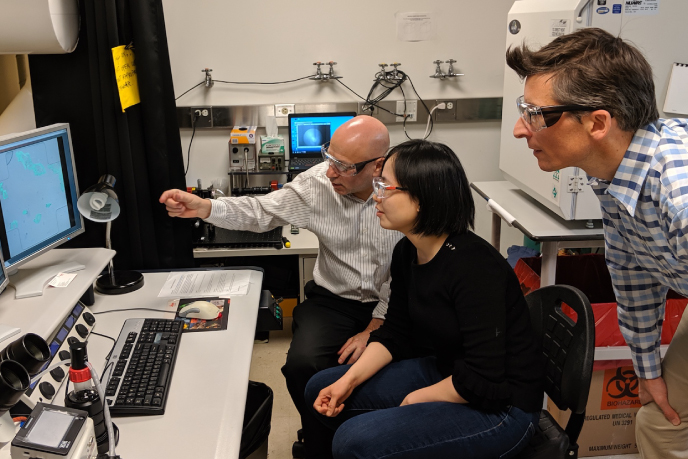

Cement durability experiments

Ed Matteo and George Scherer will use NMR to measure diffusion coefficients and a variety of techniques to measure permeability changes during leaching. We will also study the change in strength and stiffness as corrosion proceeds. To characterize the structure of the corroded cement, we will use supercritical drying to remove the pore liquid without altering the structure of the material. This is made possible by the fact that supercritical drying prevents the creation of capillary pressure, which causes collapse of the pore structure during ordinary drying. The structure will be studied using nitrogen sorption and transmission electron microscopy. This information will be needed to refine the leakage model and expand our confidence regarding the risk of leakage over the long term. Andrew Duguid’s experiments reveal that a layer of calcium carbonate precipitates in the reaction zone, resulting in a decrease in porosity and a temporary slowing of attack. It is possible that this precipitate would heal small cracks, while larger ones would be opened further. This possibility will be explored by forcing flow through cracks of controlled width to see whether there is a threshold size below which the flow is arrested.

Dynaflow development

Jean Prevost, in collaboration with Bruno Huet (now at Schlumberger, Clamart) and Lee Chin (Conoco-Philips), will complete the implementation of a geochemical module in Dynaflow that includes the constituents of cement. The geochemistry module has been developed and successfully tested against the experimental data of Andrew Duguid. The effort now is focused on improving the kinetic predictions by coupling a transport module with the geochemistry module. The remaining challenges are 1), the prediction of the change in diffusion rate as the porosity is changed by corrosion, and 2) the quantification of the advective flow driven by volume changes following chemical reactions. We will also assess the importance of pressure on the corrosion rate of cement by comparing results from the high-pressure studies at NETL to predictions from the geochemical module of Dynaflow. If necessary, improved pressure dependence will be introduced into the model.

New simulations of cement reactivity

The multiphase flash calculation has been modified to allow for pressure and temperature changes as the plume rises toward the surface, including thermal effects. This will permit us to simulate the behavior of a flow of CO2-saturated brine escaping through an annulus or crack in a well. Multiple leakage scenarios will be examined, including the impacts of varying brine composition, initial gap width, and depth at which the leak originates. The simulations will also be extended to include corrosion of the steel casing in the well.

At the end of about 2 years from today, we will be able to put bounds on the risk of leakage under unfavorable conditions (brine in a sandstone formation encountering a pre-existing annular gap in typical cement). Should we discover that the brine is quickly neutralized as it flows through the gap, so that the leak is not significantly expanded over the course of a century, then the behavior of the wells under more benign conditions is academic. On the other hand, if our simulations indicate that leaks worsen at a significant rate in sandstone formations, then we will need to see whether there is any such risk under more favorable circumstances (such as limestone formations).

Impact of injection on leakage risks

In addition to geochemical studies, Jean Prévost and Zhihua Wang will examine the potential risk from deformation of the cap rock during pressurization of the formation by injection of CO2. Owing to the difference in stiffness of the rock and the cement plugs that pass through it, there is a possibility that the cement will crack as the pressure rises, resulting in the creation of leaks. Using the poromechanical capability of Dynaflow, they will explore the circumstances under which such damage might occur.

Large-scale modeling

Moving forward, Michael Celia and colleagues plan to continue to put together models that provide quantitative estimates of the most important factors in large-scale CCS systems. These include leakage estimates for the injected CO2, and both local and basin-wide migration of displaced brine. These analyses require special modeling methods, which will be pursued through targeted combinations of numerical and semi-analytical approaches. Over the next year, the models will be implemented on massively parallel machines available at Princeton. These models will be designed to focus on subsurface behavior, but will ultimately be designed to accommodate information about surface facilities, pipelines, and other practical considerations. The aim is to create a tool that can provide a complete basin-wide analysis of how a full-scale CCS implementation will look, and what it will mean in terms of subsurface perturbations involving both CO2 and brine migration. In addition to these modeling efforts, we would like to continue to work with field engineers to enhance our experimental methodology, and encourage additional measurements so that we can begin to put together a data base that can inform risk calculations and guide injection decisions.