Coproduction of chemicals and electricity

In October 2010 the Capture group was awarded a grant from the National Energy Technology Laboratory (NETL) to investigate Energy, Environmental, and Economic Analyses of Design Concepts for the Co-Production of Fuels and Chemicals with Electricity via Co-Gasification of Coal and Biomass. Led by Larson, the early research program explored the coproduction of gasoline and electricity via co-gasification of coal and biomass in a single oxygen-blown entrained-flow gasifier.

The NETL grant co-supported additional work (beyond what was reported last year) that is described here: research on the co-production of electricity and bulk chemicals – ethylene/propylene and ammonia. This analytical extension is aimed at understanding implications for carbon mitigation and economics of systems providing, as coproducts of electricity, liquids that have higher market values than transportation fuels.

Co-producing light olefins and electricity

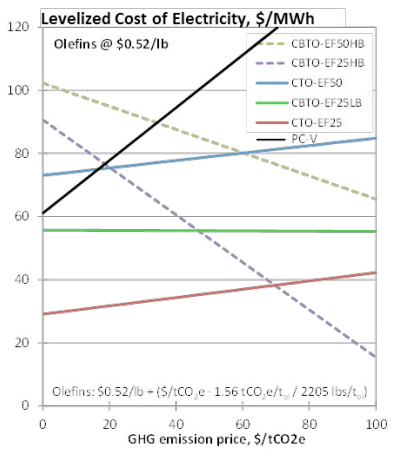

In the coproduction of light olefins and electricity, coal and torrefied biomass are first co-gasified in a dry-feed, entrained-flow gasifier. The synthesis gas from the gasifier is then converted to methanol, and the methanol is subsequently processed through a commercially-available methanol-to-olefins synthesis reactor. Both coal to olefins (CTO) and coal/biomass to olefins (CBTO) options were analyzed. Process configurations with different biomass feed percentages [HB = high (30%) biomass; LB = low (5%) biomass] and electricity output percentages (EF25 = 25% electricity; EF50 = 50% electricity) were simulated using Aspen Plus software.

Figure 8 shows some of economic findings (in $2007) from an electricity generator’s perspective. The figure shows that the options providing a 25% electricity fraction outperform the options for which electricity accounts for 50% of energy output. Moreover, the levelized cost of electricity (LCOE) for both CTO-EF25 (GHGI = 0.41) and CBTO-EF25LB with 5% biomass (GHGI = 0.30) are lower than for a new supercritical coal plant with CO2 vented (PC-V, with GHGI = 1.00) at all GHG emissions prices. For CBTO-EF25HB, which has a strong negative GHG emission rate (GHGI = – 0.32), a GHG emissions price of only $20/t CO2e is needed in order to offer the same LCOE as PC-V. The negative GHGI arises from the assumption that carbon in the olefins is sequestered permanently when products made from them are land-filled at the end of their lives.

Co-producing ammonia and electricity

Because neither electricity nor ammonia contain carbon, it is possible in a system with CCS to achieve near complete decarbonization for such systems without biomass. For this reason, only coal inputs were considered for the ammonia/electricity coproduction analyses. Two sets of coproduction cases were analyzed: one considered steady-state plant operation and a second examined potential impacts of diurnally-varying production rates aimed at exploiting higher electricity values during peak electricity demand periods.

In contrast to the findings for coproducing olefins and power, it was found that LCOE values for the steady-state ammonia-electricity coproduction cases are higher than those for PC-V plants, even assuming prices for natural gas and hence values for the ammonia (since the primary feedstock for commercial ammonia production today is natural gas) that are far higher than prices prevailing today in the U.S. and even when assuming a $100/t tCO2 e greenhouse gas emissions price.

In process simulations for plants designed to be able to vary the electricity/ammonia output ratio (producing more power when electricity is highly valued) various practical challenges were ignored— such as those associated with rapid up-and-down ramping of plant components, efficiency penalties that might occur with such ramping, and long-term maintenance and equipment fatigue issues with repeated cycling. It was found, nonetheless, that the internal rates of return for co-production were not sufficient to make this alternative plant design and operating strategy an economically viable one.

NETL-2: Co-production of jet fuel and electricity in the Ohio River Valley

In late 2012, the Capture group launched a new one-year project with co-support from a new grant from the National Energy Technology Laboratory. The goal of this work, which is still in its early stages, is to identify coal/biomass-to-liquid (CBTL) system implementation strategies for the Ohio River Valley that might increase the viability of constructing and operating such plants there in the next 5 to 10 years. The emphasis is on assessing technical and economic viability of alternative plant designs for producing primarily synthetic jet fuel that, when blended 50:50 with conventional jet fuel, will meet or beat current and potential future regulatory requirements.

Tom Kreutz is leading the design and simulation of process configurations that will include separate coal and biomass gasifiers feeding syngas to cobalt-catalyzed Fischer-Tropsch synthesis reactors. The latter produce primarily heavy paraffins that are hydrocracked and refined to aviation fuel. Designs that co-produce different levels of electricity will be assessed, and plant designs with different biomass/ coal input ratios will be analyzed. Byproduct CO2 will be captured and sold for use in enhanced oil recovery (EOR), resulting in the carbon ultimately being stored permanently underground.

The Capture group is collaborating in this project with engineers at Booz Allen Hamilton, who are contributing feedstock supply analysis and detailed lifecycle greenhouse gas accounting to complement detailed process design/simulation that will be carried out by the Capture group. The work is benefiting from a one-year visit to Princeton by Dr. Qiang Li, whose home institution is Sinopec’s Research Institute of Petroleum Processing in Beijing.