Principal Investigators

At a Glance

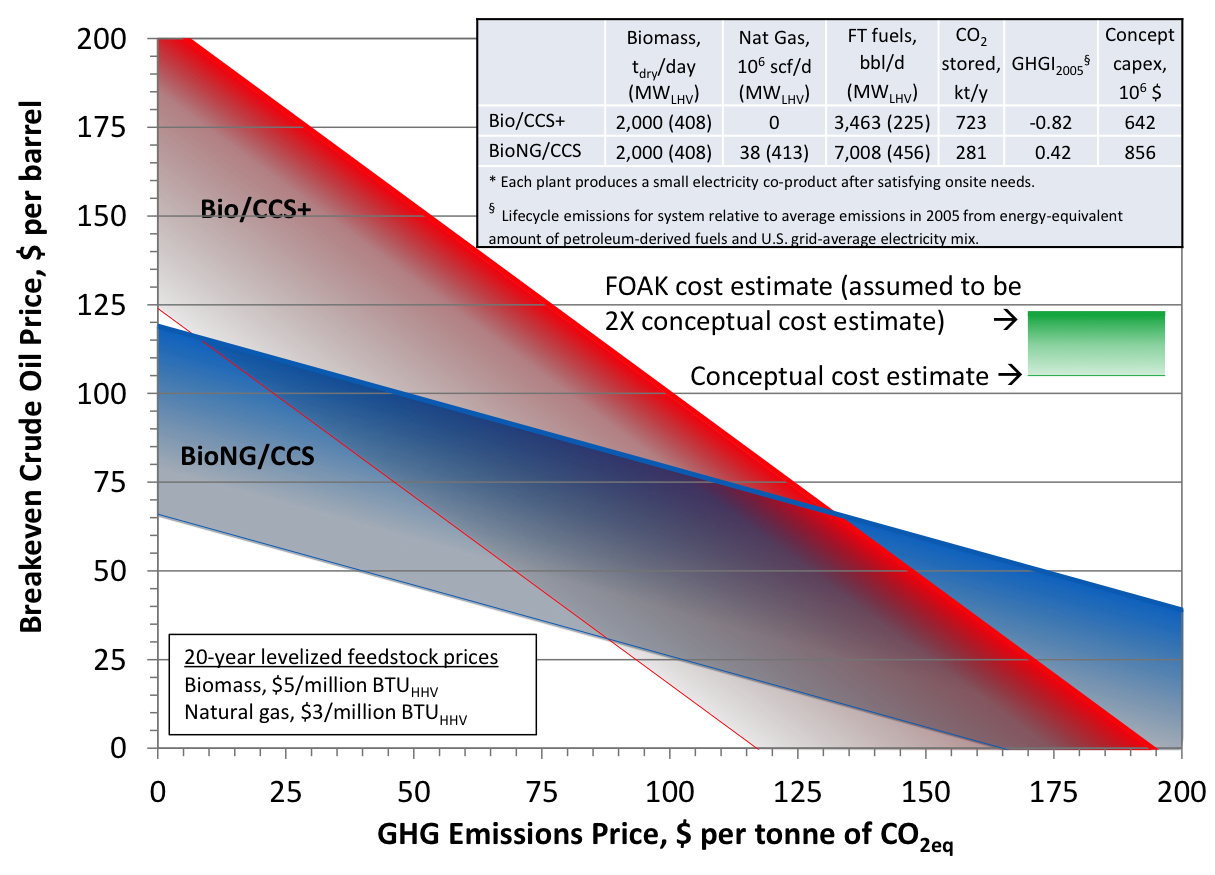

Analysis of smaller scale systems for the manufacture of low- or negative-carbon synthetic fuels from biomass and from biomass + natural gas feedstocks reveals that, in the presence of a strong carbon mitigation policy, such systems might be competitive at crude oil prices of less than $100 per barrel and would offer the opportunity for fossil fuel providers to exploit more of their fossil fuel reserves under a carbon budget constraint.

Research Highlight

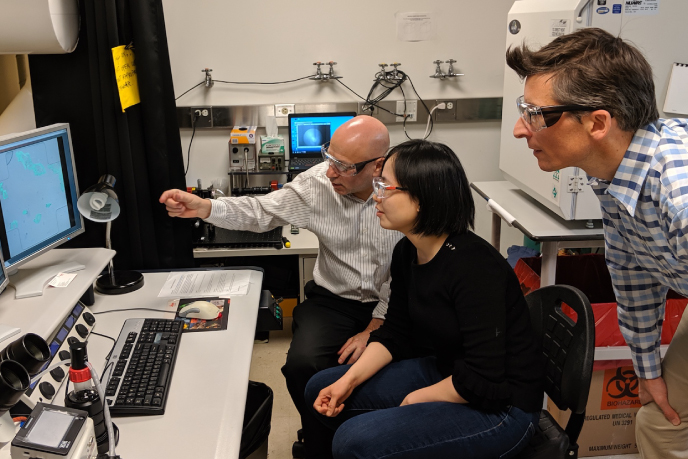

The Energy Systems Analysis group, led by Eric Larson, Robert Williams, and Thomas Kreutz, is investigating the prospective performance and economics of gasification-based systems for producing electricity and synthetic fuels from an input feedstock that is biomass or a combination of biomass and natural gas, with most carbon dioxide (CO2) emissions captured and stored (CCS systems). The group has designed systems that consume no more than 1 million dry tonnes of biomass per year, a logistical maximum that may be truck-delivered in the US to a single site. Two systems designed produce 3,500 and 7,000 barrels per day of Fischer-Tropsch (FT) synfuels, respectively, and are small relative to “gas-to-liquid” plants, such as the Pearl project in Qatar producing 140,000 barrels per day.

There are four principal arguments for investigating smaller systems:

- in contrast to the high costs for large, advanced fossil-only projects (e.g., Southern Company’s Kemper County $6.2 B integrated gasification combined cycle plant with CCS) the financial risk for investing in moderate output energy systems is lower;

- exhausted shale gas wells may offer inexpensive storage for small volumes of CO2 (280 to 720 thousand tonnes per year for the systems investigated here);

- at small scales, biomass gasifiers operated at atmospheric pressure can be used, which greatly facilitates feeding biomass into the gasifier; and

- improved synthesis economics with recent commercial development of advanced, factoryproducible reactors for catalytic synthesis of fuels in modules with capacities of a few hundred barrels per day (see Figure 2.5.1). This is far smaller than the 20,000 barrels per day capacity of conventional reactor modules used at the Pearl project.

This research examines a biomass-only “Bio/CCS+” and a hybrid natural gas “BioNG/CCS” system, each consuming about ⅔ of the maximum biomass. The hybrid system’s feedstock is about half biomass and half natural gas (on an energy basis). The outputs are synthetic FT fuels and CO2, with a small net electricity co-product (7% to 15% of energy products). Removal of CO2 from synthesis gas is already required for fuels synthesis, so there is very little incremental cost for capturing this CO2 (the expense is mainly for CO2 compression).

In collaboration with Lynn Loo (design of the plant)1 and Michael Celia (CO2 storage in shale gas wells)2, the group has explored systems that may be located over the Marcellus shale formation, a region where biomass, cheap shale gas, and pre-drilled CO2 storage sites exist. The Celia group has estimated prospective rates at which CO2 can be injected into depleted shale gas wells in the Marcellus formation, and these are well-matched to the CO2 capture rates for the two systems.

The lifecycle greenhouse gas (GHG) emissions (in metric tonnes of equivalent CO2eq per unit of liquid fuel energy, denoted as t CO2eq, including contributions from the plant and from fuel combustion in a vehicle, are significantly lower than from equivalent petroleum-derived fuels: if petroleum-fuel emissions are taken, for reference, to be +1, emissions for BioNG/CCS are +0.42 and for BioCCS+ are -0.82. In the BioNG/CCS case, CO2 storage accounts for 15% of the carbon in the feedstocks, and 36% is vented at the plant. In the Bio/CCS+ case, 59% of input biomass carbon is stored underground as CO2, and only 4% is vented.

Figure 2.5.2 shows bands of prices of crude oil that would make each of these options competitive with petroleum-derived fuels, at various GHG emissions prices. The tops of the bands represent first of-a-kind (FOAK) plants with capital costs assumed to be twice those developed in this conceptual estimating study3. Experience might lead to cost reductions (“learning by doing”) equivalent to fractions of these bands. The calculations assume a well-head gas price of $3 per million BTU and a biomass cost of $5 per million BTU, with CO2 stored in nearby spent shale gas wells. With FOAK capital costs and with zero GHG emissions price, fuels produced via a BioNG/CCS built in the near term would be competitive with petroleum-derived fuels when the oil price is $120 per barrel while Bio/CCS+ requires a crude oil price 70% higher. The BioNG/CCS is more competitive than Bio/ CCS+ due primarily to lower feedstock costs and secondarily to scale-economy benefits and process efficiency improvements. A price on GHG emissions makes both systems more competitive and affects the Bio/CCS+ system the most, i.e., the breakeven oil price for Bio/CCS+ falls rapidly with increasing GHG emission price. The two cost lines for FOAK systems cross at $65 per barrel, when the GHG emissions price is about $130/t CO2eq.

According to the Intergovernmental Panel on Climate Change (IPCC), if the global community were on an energy track consistent with limiting global warming to 2°C under market-based climatechange-mitigation policies, the GHG emissions price would rise (in 2012 $) from almost $60/t CO2 in 2020 to $100/t in 2032 and to more than $220/t in 20504 . This work suggests that for such an emissions price trajectory BioNG/CCS might be economically deployed early in the next decade, and that Bio/CCS+ systems could become attractive options soon thereafter. The IPCC has also shown that if likely global warming is to be limited to no more than 2°C, biomass energy with carbon capture and storage (BECCS) technologies that provide negative emissions will probably be needed4 to stay within the allowable remaining cumulative CO2 emissions (about 1 trillion tonnes5 ): BECCS systems with negative emissions could provide an opportunity for carbon credits that would enable a fossil fuel provider to use more of its fossil fuel reserves under such a carbon budget constraint.

The Energy Systems Analysis Group will expand its investigation of alternative processes for production of low and negative emissions liquid transportation fuels, including pyrolytic and biochemical systems, as well as additional gasification-based pathways with and without fossil fuel coprocessing.

References

- Hailey, A.K., J.C. Meerman, E.D. Larson, and Y-L. Loo, 2015. Co-processing Biomass and Natural Gas into Clean Transportation Fuels at Small Scale. Manuscript in preparation, February, 2015.

- Edwards, R.W.J., M.A, Celia, C.M. Kanno, K.W Bandilla, and F. Doster, 2014. Investigating the Potential for Large-Scale Carbon Dioxide Sequestration in Shale Gas Formations. Abstract H1D-03, AGU Fall Meeting (San Francisco, CA), 15-19 December, 2014.

- Greig, C., A. Garnett, J. Oesch, and S. Smart, 2014. Guidelines for Scoping and Estimating Early Mover CCS Projects, Milestone 5, Final Report. Univ. Queensland, Brisbane, Australia, 19 June, 2014.

- Intergovernmental Panel on Climate Change (IPCC), 2014. Climate Change 2014: Mitigation of Climate Change, Working Group III contribution to the Fifth Assessment Report, April, 2014.

- Intergovernmental Panel on Climate Change (IPCC), 2014. Climate Change 2014: Mitigation of Climate Change, Working Group I contribution to the Fifth Assessment Report, April, 2014.

- McDaniel, J. (Velocys, Inc.), 2014. Commercial deployment of smaller scale GTL in North America. Energy Frontiers Gas-to-Market and Energy Conversion Forum (Pittsburgh, PA), October, 2014